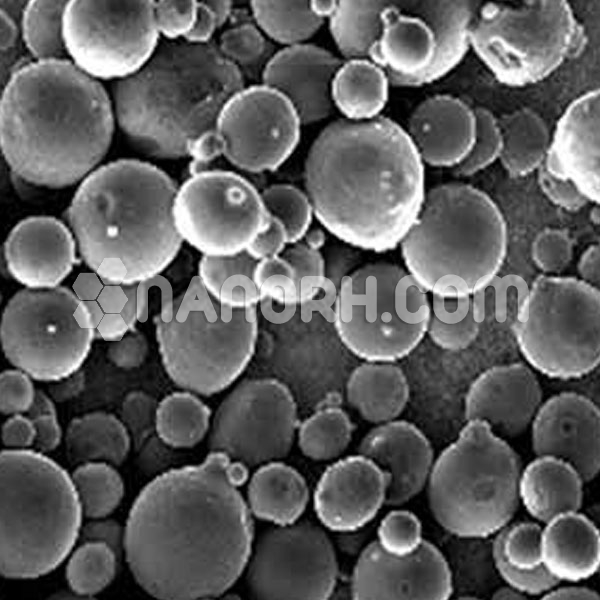

| Atomized spherical mg alloy powder | |

| Product No | NRE-60102 |

| Purity | 99.9% |

| Mesh | 15-53 mesh |

| Color | Silver Gray |

| AZ91D | |||||||||

| Composition | Mg | Al | Cu | Fe | Mn | Ni | Si | Zn | Be |

| wt% | 90.43 | 8.90 | 0.0006 | 0. 0112 | 0.19 | 0.003 | 0.003 | 0.4278 | 0.00098 |

| ZK61 | |||||||||

| Composition | Mg | Zr | Zn | Fe | Mn | Ni | Si | Cu | Al |

| wt% | 94.46 | 0.33 | 5.1953 | 0.0035 | 0.0055 | 0.003 | 0.0007 | 0.0010 | 0.0006 |

| WE43 | ||||||||

| Composition | Y | Re | Zr | Fe | Si | Cu | Ni | Mg |

| wt% | 4.01 | 3.04 | 0.51 | 0.00713 | 0.00400 | 0.00370 | 0.00432 | balance |

Atomized spherical magnesium alloy powder

Our atomized mg alloy spherical powder can be widely used in 3D printing materials, aerospace, electronic packaging, powder metallurgy, drilling rigs fracturing ball seats, and other fields.

High purity atomized spherical mg alloy powder is known for the outstanding performance of high bulk density, high active magnesium content, high fluidity, high stability, small particle size and small specific surface area, and so on.

High purity atomized mg alloy spherical powder is widely used in fields such as aviation, national defense, composite materials, powder metallurgy, petrochemical catalyst, electronic coatings, medicine,

Metal spherical powder, often produced through processes like atomization or gas atomization, possesses unique characteristics that make it suitable for various applications. The spherical shape of the particles contributes to improved flowability, packing density, and surface area, making them advantageous in a range of industries. Here are some applications of metals spherical powder:

Additive Manufacturing (3D Printing):

Metal spherical powders are widely used in additive manufacturing processes, particularly in metal 3D printing. The spherical shape promotes uniform powder spreading, leading to enhanced layer-by-layer printing accuracy. Common metals used include titanium, aluminum, stainless steel, and nickel alloys.

Powder Metallurgy:

Metal powders are extensively employed in powder metallurgy processes to produce various components and parts. Spherical powder enhances the packing density and flowability during the compaction and sintering stages, resulting in improved mechanical properties of the final product.

Surface Coating:

Spherical metal powders are used in the production of coatings for various applications, such as thermal spraying and plasma spraying. These coatings provide enhanced wear resistance, corrosion resistance, and thermal insulation to the substrate material.

Chemical Catalysts:

Some metals, in spherical powder form, are used as catalysts in chemical reactions. The high surface area and reactivity of the spherical particles make them effective in promoting chemical transformations.

Electronics and Electrical Components:

Some metals in spherical powder form are used in the production of conductive inks for printed electronics. These inks can be applied to flexible substrates for the fabrication of electronic components.

Energy Storage:

Spherical powders are used in the production of electrodes for batteries and fuel cells. The high surface area and controlled particle size distribution are critical for optimizing the performance of energy storage devices.

Atomized spherical magnesium alloy powder has several applications due to its unique properties. Here are some of the common applications:

Additive Manufacturing (3D Printing): Magnesium alloy powders can be used in additive manufacturing processes, such as powder bed fusion (selective laser melting or electron beam melting), to produce lightweight and high-strength components. This is particularly useful in aerospace and automotive industries.

Coating and Surface Treatment: Atomized spherical magnesium alloy powder can be used as a coating material for corrosion protection or as a surface treatment to enhance the wear resistance of various components. This is important in industries where protection against environmental factors is crucial.

Energetic Materials: Magnesium alloy powders can be utilized in the production of energetic materials, such as propellants and explosives. The high reactivity of magnesium contributes to the energy release in these applications.

Catalyst Support: Atomized spherical magnesium alloy powder can be used as a catalyst support material, especially in heterogeneous catalysis. The high surface area and uniform particle size distribution make it suitable for catalytic applications in various chemical processes.

Biomedical Applications: Magnesium alloys are of interest in the biomedical field due to their biodegradability and biocompatibility. Spherical magnesium alloy powder can be used in the manufacturing of biodegradable implants and devices for medical applications.

Thermal Spray Coatings: Magnesium alloy powders can be used in thermal spray processes to produce protective coatings on surfaces, providing enhanced resistance to wear, corrosion, and temperature.

Metal Foams Production: The production of lightweight metal foams, which find applications in automotive and aerospace industries, often involves the use of magnesium alloy powders. These powders can be incorporated into foam manufacturing processes to create lightweight and strong materials.