| Boron Carbide Nanopowder | |

| Product No | NRE-5032 |

| CAS No. | 12069-32-8 |

| Formula | B4C |

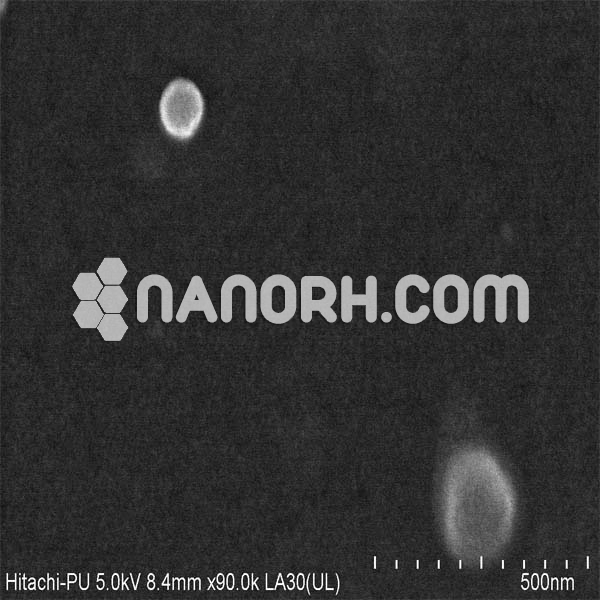

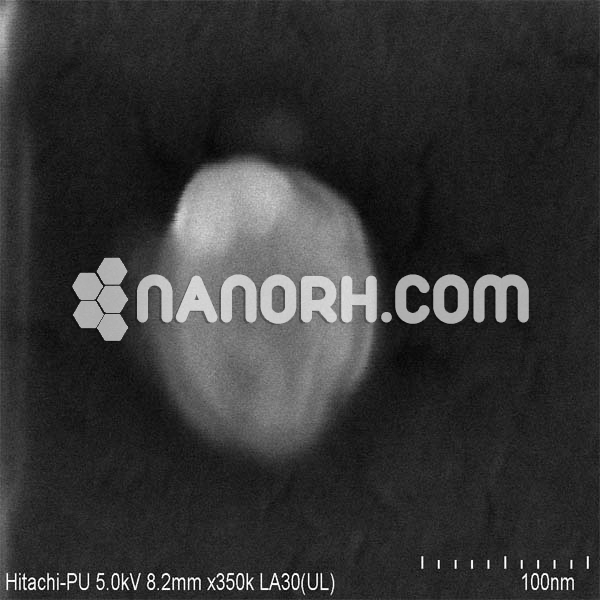

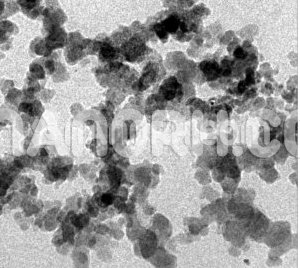

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Black |

| Molecular Weight | 55.251 g/mol |

| Density | 2.51 g/mL |

| Melting Point | 2,763 °C |

| Boiling Point | 3,500 °C |

Boron Carbide Nanopowder

Boron Carbide Nanopowder also known as black diamond, is the third hardest material (after diamond and cubic boron nitride, c-BN). Above 1300 ◦C, it is even harder than diamond and c-BN. With good chemical resistance and large neutron capture cross section, it can be used in many areas, such as radiation shielding, abrasive tools, etc. Due to its low density (2.52 g / cm3), one of the important applications is for high performance body protection plates, which are mainly produced by hot pressing, in tank armor, bulletproof vests, engine sabotage powders, as well as numerous industrial applications. Boron Carbide Nanopowder can be prepared by various methods, such as the carbon thermal path of boron oxide. The industrial method for culturing B4C is the thermal carbon reduction of boric acid at a temperature above 2000 ◦C. At low temperatures (450 ◦C), B4C Nanopowder can be produced using BBr3 and CCl4 as reactants and metallic Na as co-reluctant. The hardness and yield strength of any material generally increase as the grain size decreases. Commercially available B4C has a particle size of approximately microns. In Nano Research Elements with the use of a solid vapor reaction we create uniformly sized B4C Nanopowder below 100 nm. This nano-sized particle significantly improve mechanical properties, especially toughness.