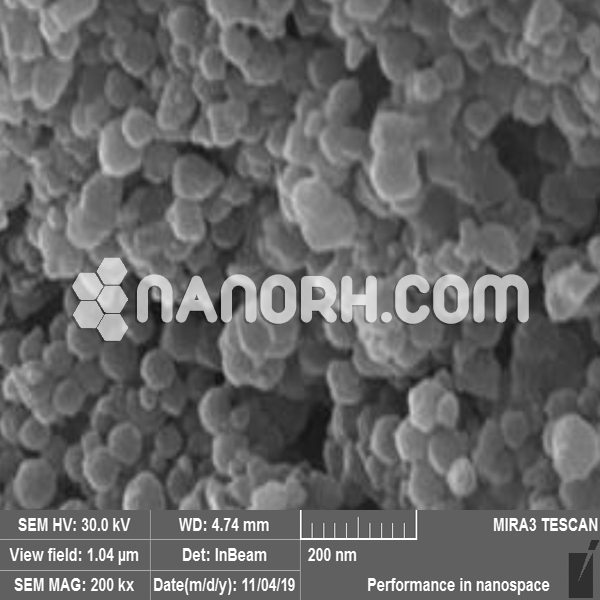

Chromium Carbide (Cr3C2) Nanopowder / Nanoparticles (Cr3C2, 30-120nm, 99.7+%, Gray, Orthorhombic Crystal Structure)

Chromium carbide (Cr3C2) is a to a great degree hard recalcitrant earthenware material. It is generally prepared by sintering. It resembles a dark powder with orthorhombic precious stone structure. The orthorhombic Cr3C2 happens to a great degree infrequently as mineral tongbaite. It is profoundly consumption safe, and does not oxidize even at high temperature (1000-1100 °C). The warm development coefficient of chromium carbide is practically equivalent to that of steel, lessening the mechanical anxiety development at the layer limit. Precipitation of chromium carbide at the grain limits, draining the grain edges of chromium, is the reason for intergranular erosion of stainless steel close to the welds

| Chromium Carbide Nanoparticles | |

| Product No | NRE-5059 |

| CAS No. | 12012-35-0 |

| Formula | Cr3C2 |

| APS | <120nm (Can be Customized) |

| Purity | 99.9% |

| Color | Gray-Brown |

| Molecular Weight | 180.0097 g/mol |

| Density | 6.68 g/cm3 |

| Melting Point | 1895°C |

| Boiling Point | 3800°C |

Chromium carbide Nanoparticles (Cr3C2)

Properties and Applications:

Chromium carbide (Cr3C2) is a to a great degree hard recalcitrant earthenware material. It is generally prepared by sintering. It resembles a dark powder with an orthorhombic precious stone structure. The orthorhombic Cr3C2 happens to a great degree infrequently as mineral tongbaite. It is profoundly consumption safe and does not oxidize even at high temperatures (1000-1100 °C). The warm development coefficient of chromium carbide is practically equivalent to that of steel, lessening the mechanical anxiety development at the layer limit. Precipitation of chromium carbide at the grain limits, draining the grain edges of chromium, is the reason for the intergranular erosion of stainless steel close to the welds. Chromium carbide is utilized as a warm shower material for securing the basic metal surface, and as an added substance to erosion safe and wear-safe materials. It is utilized as a part of coatings, of course, seals, openings, and valve seals, and as a fine-gem stage in other sintered carbides, where, similar to the vanadium carbide, it represses the development of submicrometre grains amid squeezing and sintering.