Cobalt Chromium Aluminium Yttrium Alloy Nanoparticles

Cobalt Chromium Aluminium Yttrium Alloy Nanoparticles

| Cobalt Chromium Aluminium Yttrium Alloy Nanoparticles | |

| Product No | NRE- 2007 |

| CAS No. | NA |

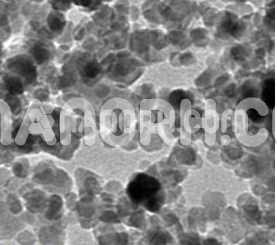

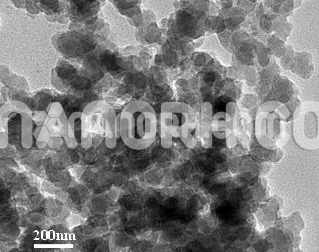

| Formula | CoCrAlY |

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Gray |

| Molecular Weight | 226.81 g/mol |

| Density | NA |

| Melting Point | NA |

| Boiling Point | NA |

Cobalt Chromium Aluminium Yttrium Alloy Nanoparticles

Applications

Aerospace Industry:

CoCrAlY nanopowders are widely used in aerospace applications, particularly for turbine blades, jet engine components, and heat shields. Their high-temperature resistance, corrosion resistance, and wear resistance make them ideal for materials that need to withstand the extreme conditions encountered in gas turbines and jet engines. These alloys help improve the performance and longevity of key components exposed to high heat and oxidizing environments.

Energy Production:

In the energy sector, CoCrAlY nanopowders are used in power plants, gas turbines, and boilers. The ability to maintain high strength and oxidation resistance at elevated temperatures makes them essential for components that operate under constant high-temperature and oxidative stress. The improved thermal stability and corrosion resistance help increase the efficiency and lifespan of energy production equipment.

Protective Coatings:

CoCrAlY nanopowders are commonly used to produce thermal barrier coatings and protective coatings for aerospace, automotive, and marine applications. The coatings protect critical components from the damaging effects of high temperatures, corrosion, and wear. The yttrium in the alloy enhances the adhesion and durability of these coatings, allowing them to perform effectively in extreme environments.

Biomedical Applications:

CoCrAlY nanopowders are explored for use in biomedical implants, such as joint replacements and dental implants, due to their biocompatibility, wear resistance, and corrosion resistance. The material can be used to create implants that can endure the stresses and abrasion that come with body movements. The yttrium content helps further improve the alloy’s compatibility with biological systems.

Industrial Machinery:

CoCrAlY nanoparticles are applied in industrial machinery, particularly in cutting tools, machinery components, and seals that are exposed to abrasion, corrosion, and extreme temperatures. The nanopowder’s wear resistance, high strength, and thermal stability improve the lifespan and efficiency of machinery parts in various manufacturing processes.