| Cobalt Oxide Sputtering Target | |

| Product No | NRE-43033 |

| CAS No. | 1307-96-6 |

| Formula | CoO |

| Molecular Weight | 74.9326 g/mol |

| Purity | 99.99% |

| Density | 6.44 g/cm³ |

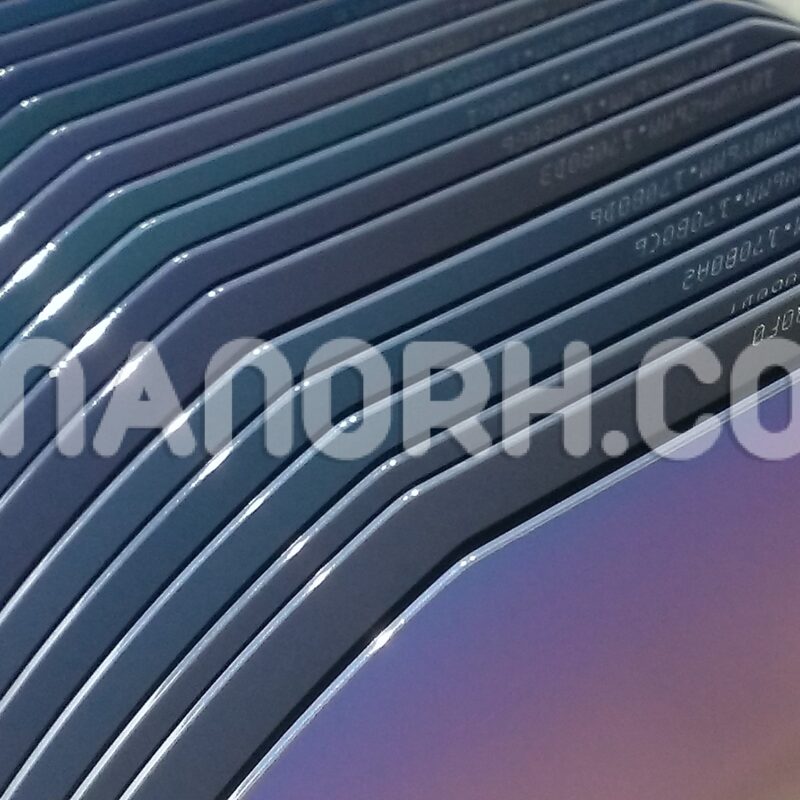

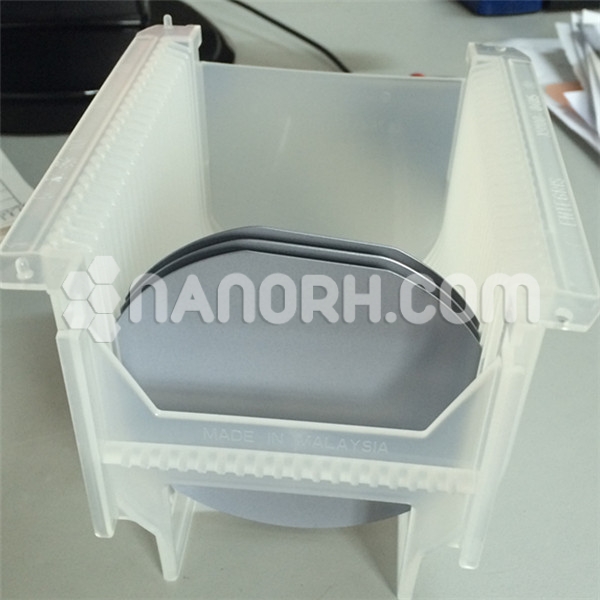

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Expansion | NA |

Cobalt Oxide Sputtering Target

Cobalt oxide sputtering targets are versatile materials with a wide range of applications across various industries. Their properties, such as catalytic activity, electrical conductivity, optical characteristics, and stability, make them suitable for diverse uses. Here’s a detailed breakdown of different applications and how cobalt oxide sputtering targets are deployed in these fields.

Catalysis

Industrial Catalysts:

Deployment: Cobalt oxide, especially Co₃O₄, is used to deposit thin films on catalytic substrates. These catalysts are employed in chemical reactors for processes like the oxidation of hydrocarbons and the water-gas shift reaction.

Applications: Petrochemical refining, environmental pollution control, and synthesis of chemicals and fuels.

Fuel Cells:

Deployment: Co₃O₄ thin films are applied to electrodes in fuel cells. This enhances the efficiency of the oxygen reduction and evolution reactions.

Applications: Hydrogen fuel cells, direct methanol fuel cells.

Battery Technology

Lithium-Ion Batteries:

Deployment: Cobalt oxide sputtering targets are used to create thin films of lithium cobalt oxide (LiCoO₂) for use as the positive electrode material in lithium-ion batteries.

Applications: Consumer electronics (smartphones, laptops), electric vehicles, and energy storage systems.

Electrochromic Devices

Smart Windows:

Deployment: Co₃O₄ thin films are applied to glass or plastic substrates to create electrochromic layers that can change color or opacity in response to an electric current.

Applications: Energy-efficient windows, displays, and smart glass technologies.

Sensors

Gas Sensors:

Deployment: Cobalt oxide thin films are deposited on sensor substrates to detect gases such as carbon monoxide (CO) and methane (CH₄). The material’s catalytic properties enhance the sensor’s sensitivity and response.

Applications: Environmental monitoring, industrial safety, automotive emission control.

Optical Coatings

Antireflective Coatings:

Deployment: Co₃O₄ thin films are used to coat optical surfaces, modifying their refractive index to reduce glare and enhance optical performance.

Applications: Lenses, eyeglasses, camera lenses, and other optical devices.

- Magnetic Materials

Magnetic Thin Films:

Deployment: Co₃O₄ thin films are applied to create magnetic materials used in sensors and data storage devices.

Applications: Magnetic sensors, read/write heads in hard disk drives, and other magnetic recording media.

Supercapacitors

Energy Storage:

Deployment: Co₃O₄ thin films are used in supercapacitors to enhance energy and power density by providing high pseudocapacitance.

Applications: Energy storage systems, power backup, and rapid charge/discharge applications.