Fe-Ni-Co Alloy Nanopowder / Nanoparticles (99.9%, <100nm, Fe:Ni:Co/55:28:17)

Fe-Ni-Co Alloy Nanopowder

| Fe-Ni-Co Alloy Nanoparticles | |

| Product No | NRE- 2022 |

| CAS No. | 7439-89-6/7440-02-0/7440-48-4 |

| Formula | Fe-Ni-Co |

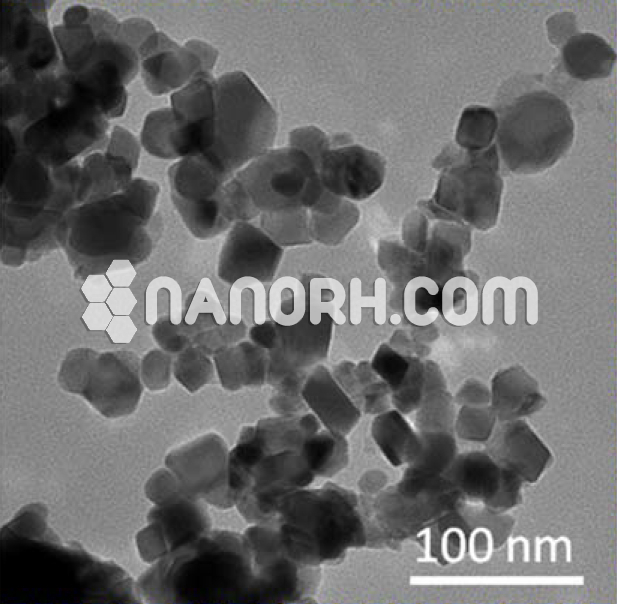

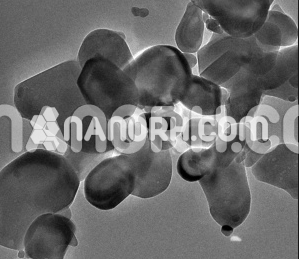

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Black Grey |

| Molecular Weight | 173.4716 g/mol |

| Density | 8.25 g/cm3 |

| Melting Point | 1450°C |

| Boiling Point | NA |

Fe-Ni-Co Alloy Nanopowder

Fe-Ni-Co Alloy nanoparticles refers to a composite material composed of three ferromagnetic metals—iron fe-ni-co alloy nanoparticles combined in various proportions at the nanoscale. These nanoparticles typically range in size from 1 to 100 nanometers and possess unique properties that make them highly desirable for a wide range of technological applications.

Structure and Synthesis

The structure of is defined by the atomic arrangement of iron, nickel, and cobalt. These elements form a solid solution in various proportions, and the specific ratio of the elements can be tailored to meet the requirements of different applications. Fe-Ni-Co alloys can form different crystal structures depending on the relative amounts of each element, but they often exhibit a face-centered cubic (FCC) or hexagonal close-packed (HCP) structure, both of which contribute to their excellent magnetic and mechanical properties.

The production of typically involves advanced nanomaterial synthesis methods that allow for precise control over the size, shape, and composition of the nanoparticles.

Chemical reduction: A common approach where metal salts are reduced using chemical agents to form nanoparticles.

Sol-gel methods: A process involving the transition of a liquid solution into a solid gel, followed by heat treatment to produce nanoparticles.

Hydrothermal synthesis: A technique where the alloy is synthesized under high-temperature and high-pressure conditions, leading to the formation of nanoparticles with specific properties.

Mechanical milling: A technique where bulk materials are subjected to mechanical forces to break them into fine nanoparticles.