| Gold Palladium Sputtering Target | |

| Product No | NRE-43058 |

| CAS No. | 12006-59-6 |

| Formula | AuPd |

| Molecular Weight | 303.39 g/mol |

| Purity | 99.99% |

| Density | 16 g/cm3 |

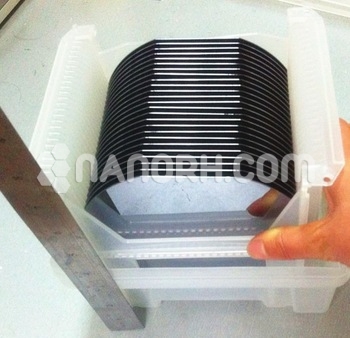

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Expansion | NA |

Gold Palladium Sputtering Target

Introduction

Gold palladium (AuPd) sputtering target are materials composed of an alloy of gold and palladium, utilized in the sputtering process to deposit thin films of this alloy onto various substrates. Both gold and palladium possess excellent electrical conductivity, corrosion resistance, and catalytic properties, making them valuable in a wide range of applications.

Applications

Microelectronics:

Interconnects: Gold Palladium Sputtering Target is often used in semiconductor manufacturing for electrical interconnects due to its excellent conductivity and reliability.

Thin-Film Coatings:

Catalytic Coatings: The alloy can serve as a catalyst in various chemical reactions, including in sensors and fuel cells, where its catalytic properties enhance performance.

Optoelectronics:

Optical Coatings: Gold-Palladium Sputtering Target thin films are employed in optical applications, such as in coatings for mirrors or other components that require high reflectivity and stability.

Biomedical Devices:

Biocompatibility: Due to its biocompatibility, AuPd is used in medical devices and implants, particularly in applications that involve direct contact with biological tissues.

Sensors:

Gas Sensors: The alloy can be used in gas sensing applications, leveraging its catalytic properties to detect various gases.

Jewelry and Decorative Applications:

Alloy Properties: AuPd is also used in the jewelry industry for making durable and aesthetically appealing items, taking advantage of its resistance to tarnish and corrosion.

Sputtering is typically used in semiconductor manufacturing, optics, and decorative coatings. The choice of gold-palladium targets can depend on specific application requirements, including the desired thickness, uniformity, and film composition.