Highly Conductive Graphene Nanotubes

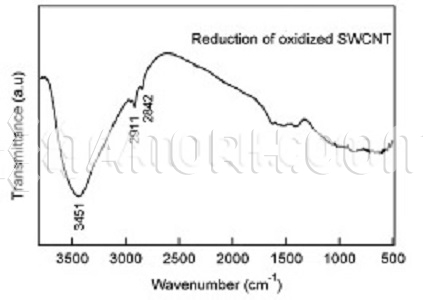

Effectively improve the electrical conductivity, thermal conductivity and mechanical properties; Effectively enhance tensile strength, hardness and elastic modulus characteristics. Also, Higher electrode conductivity and stronger electrode mechanical strength and adhesive attraction; The product is composed of high electric conductive CNTs and graphene and highly conductive carbon black nanopowder. The carbon black nanoparticles can not only prevent dispersed CNTs and graphene from reagglomerating, but also exhibit synergetic effect with CNTs and graphene.

| Highly Conductive Graphene Nanotubes | |

| Product No | NRE-39018 |

| CAS No. | NA |

| Purity | > 97% |

| Average Diameter | >55 nm |

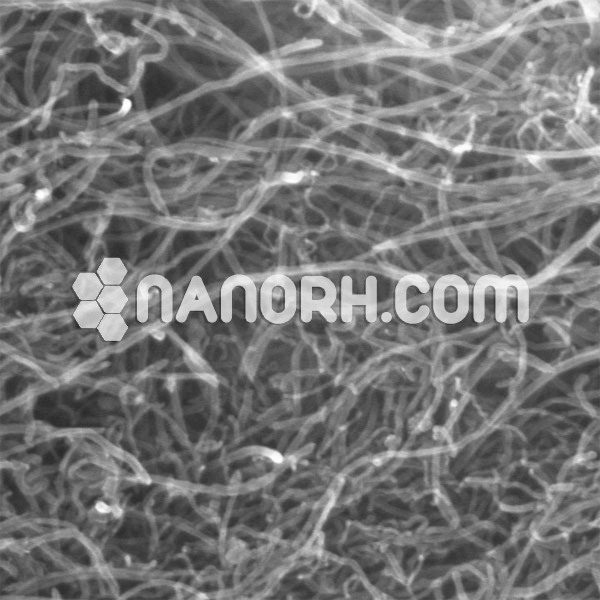

| Average Length | 10-30 um (TEM) |

| Special Surface Area(SSA) | > 60 m2/g (BET) |

| Tap Density | 0.12 g/cm3 |

| True Density | 2.1 g/cm3 |

| Electric Conductivity | >100 s/cm |

Highly Conductive Graphene Nanotubes

Introduction

Highly Conductive Graphene Nanotubes (GNTs) are an innovative hybrid material that combines the remarkable properties of graphene and carbon nanotubes (CNTs). They consist of graphene sheets rolled into nanotube structures, blending the strengths of both materials to create a highly conductive, lightweight, and mechanically robust material with a wide range of potential applications.

Applications

Electronics and Conductive Materials

Flexible Electronics: One of the most exciting applications of GNTs is in the field of flexible electronics. GNTs can be incorporated into conductive inks and used for the printing of electronic circuits onto flexible substrates like plastic, textiles, or paper. This enables the development of lightweight, flexible, and low-cost electronics such as wearable devices, smart textiles, and flexible displays.

Conductive Inks and Pastes: GNTs are used to create conductive inks and adhesives for printing electronic circuits, sensors, and antennas. These inks can be applied in the printed electronics industry for applications such as RFID tags, solar cells, and electronic labels.

Transparent Conductive Films: GNTs, combined with graphene, can be used to produce transparent conductive films. These films are ideal for use in touchscreens, OLEDs, solar panels, and flat-panel displays. The excellent conductivity and transparency of GNTs allow for the creation of thin, flexible, and transparent conductive materials that outperform traditional metals like indium tin oxide (ITO).

High-Performance Transistors: GNTs are also being explored for use in high-performance field-effect transistors (FETs), which form the backbone of modern semiconductor electronics. Due to their superior conductivity and small size, GNTs enable faster switching speeds and miniaturization of electronic components.

Energy Storage and Supercapacitors

Supercapacitors: GNTs are used to improve the performance of supercapacitors, which are energy storage devices that provide high power density and rapid charge/discharge rates. GNTs enhance the surface area and electrical conductivity of electrodes, leading to supercapacitors that are more efficient, last longer, and store more energy. This makes them ideal for applications in electric vehicles, wearable electronics, and energy harvesting.

Batteries: Lithium-ion and sodium-ion batteries can benefit from the incorporation of GNTs in their electrode materials. The GNTs enhance the conductivity of the electrodes, improving the charge/discharge cycles and energy density of the batteries. This is particularly valuable for applications requiring high-energy storage, such as electric vehicles, grid energy storage, and portable devices.

Supercapacitor-Battery Hybrids: GNTs are also used in hybrid energy storage devices that combine the best features of both batteries and supercapacitors. These supercapacitor-battery hybrids offer high energy density (from the battery component) and fast power delivery (from the supercapacitor component), making them suitable for applications in electric vehicles, smart grids, and renewable energy systems.