Magnesium coated Carbon Nanotubes (Mg/CNT)

| Magnesium coated Carbon Nanotubes | |

| Product No | NRE-42003 |

| CAS No. | 7439-95-4/308068-56-6 |

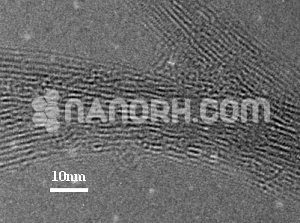

| Outer Diameter | 35-50 nm |

| Inner Diameter | 5-25nm |

| Average Length | 10-20um |

| True Density | 2.1 g/cm3 |

| Electric Conductivity | > 100 S/cm |

| Metal Percentage | 2-5% (can be Customized) |

Magnesium coated Carbon Nanotubes– CNTs decorated with metal nanoparticles (NPs) like Silver nanoparticles, Gold nanoparticles, Nickel nanoparticles, copper nanoparticles, Magnesium nanoparticles, palladium nanoparticles, platinum nanoparticles, exhibit outstanding chemical activity due to their large active surface area and unique crystallographic surface structure.

Magnesium coated Carbon Nanotubes– exhibit outstanding chemical activity due to their large active surface area and unique crystallographic surface structure.

Applications

Lightweight Structural Materials

Automotive and Aerospace Industries: Mg-CNT composites can be used in the manufacture of lightweight, high-strength components for vehicles and aircraft. Reducing the weight of structural materials in these industries leads to better fuel efficiency, lower emissions, and enhanced performance.

Construction Materials: The strength and light weight of Mg-CNT composites make them suitable for use in advanced construction materials. These could include lightweight, durable building materials for infrastructure projects.

Energy Storage and Batteries

Supercapacitors: Magnesium-coated CNTs can be used in energy storage devices such as supercapacitors, where the high surface area of CNTs and the lightweight, conductive magnesium coating enhance the energy storage capacity and charge/discharge efficiency.

Batteries: Magnesium is also being studied as an anode material for rechargeable batteries (such as magnesium-ion batteries), and the addition of CNTs helps improve the electrical conductivity and stability of these batteries, leading to better performance in energy storage applications.

Catalysis

Catalytic Reactions: Magnesium-coated CNTs can act as catalysts or catalytic supports in chemical reactions. The unique properties of magnesium, combined with the high surface area of CNTs, make this composite useful in processes like hydrogenation, dehydrogenation, and other reactions in the chemical industry.

Hydrogen Storage and Fuel Cells: Magnesium is a promising material for hydrogen storage because of its ability to absorb large amounts of hydrogen. When combined with CNTs, Mg-CNT composites can be used to develop more efficient hydrogen storage materials for fuel cells and other clean energy technologies.

Thermal Management

Heat Dissipation: Magnesium-coated CNTs retain much of CNTs’ excellent thermal conductivity. These composites can be used in heat sinks and other thermal management systems for electronic devices, such as processors or LEDs, where efficient heat dissipation is required.

Thermal Interface Materials: Mg-CNTs can be used in thermal interface materials (TIMs), which are essential for ensuring efficient heat transfer between electronic components (e.g., between chips and heat sinks).