| Molybdenum Rhenium Alloy Sputtering Targets | |

| Product No | NRE-43501 |

| CAS No. | NA |

| Formula | Mo-Re |

| Molecular Weight | NA |

| Purity | >99.9% |

| Density | NA |

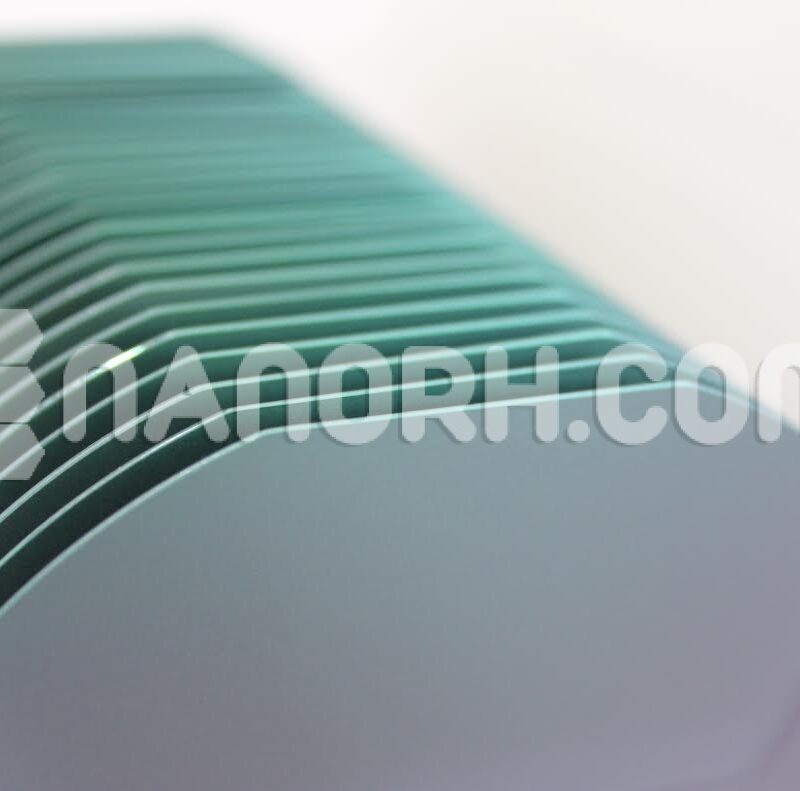

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Molybdenum Rhenium Alloy Sputtering Targets

Introduction

Molybdenum rhenium (Mo-Re) alloy sputtering targets are specialized materials used in physical vapor deposition (PVD) processes to produce thin films and coatings. This alloy combines molybdenum, known for its high melting point and mechanical strength, with rhenium, which enhances ductility and improves the alloy’s performance at elevated temperatures. The combination of these two metals results in an alloy that retains desirable properties from both, making it suitable for high-performance applications.

Applications

Electronics:

Thin Film Transistors (TFTs): Used in the production of TFTs for display technologies, providing stable and conductive layers.

Interconnects: Employed as interconnect materials in integrated circuits, benefiting from their excellent conductivity and mechanical properties.

Aerospace and Defense:

High-Temperature Components: The alloy is used in components exposed to high temperatures and stresses, such as those found in jet engines and rocket nozzles.

Superconducting Films: Mo-Re alloys can be used to fabricate superconducting thin films, which are essential for various electronic and magnetic applications, including MRI machines.

Wear-Resistant Coatings:

The alloy can be applied as a protective coating on tools and machinery components, enhancing wear resistance and extending service life.

Optoelectronics:

Utilized in certain optoelectronic devices, leveraging its unique optical properties and stability.