| Nickel Titanium Alloy Powder | |

| Product No | NRE-9030 |

| CAS No. | 7440-02-0/7440-32-6 |

| Formula | Ni-Ti |

| Molecular Weight | 106.5604 g/mol |

| APS | <40 um (Can be Customized) |

| Purity | 99.9% |

| Density | 6.45 g/cm3 |

| Color | Gray |

| Melting Point | 1310°C |

| Boiling Point | NA |

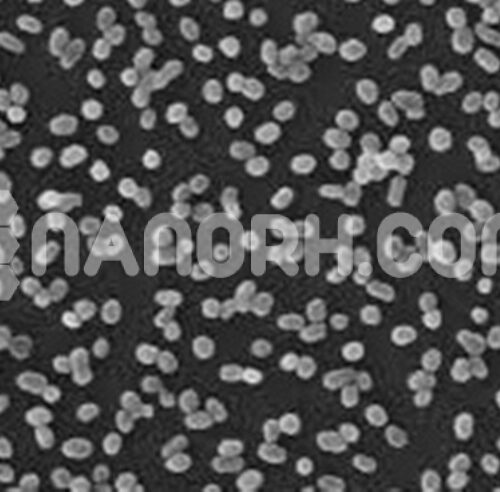

nickel-titanium-alloy- Powder

Applications

Medical and Biomedical Applications:

Ni-Ti alloys are extensively used in the medical field due to their biocompatibility, corrosion resistance, and shape memory effect. Common applications include:

Stents: Nickel-titanium alloys are widely used in vascular stents, as their superelasticity allows them to expand and fit perfectly in arteries, promoting blood flow without the risk of being rejected by the body.

Orthodontic Braces: Ni-Ti alloy wire is commonly used in dental braces due to its shape memory effect, helping to apply consistent pressure over time to move teeth into position.

Surgical Instruments: Ni-Ti alloys are used for minimally invasive surgical tools and guidewires, as they are flexible and resistant to corrosion in body fluids.

Implants: The alloy is also used for orthopedic implants and bone staples, where flexibility, strength, and biocompatibility are crucial.

Aerospace and Defense:

Nickel-titanium alloy powder is used in aerospace applications for parts that require superelasticity and the ability to withstand extreme environments. These include components like:

Actuators and smart structures: Nitinol’s shape memory effect is harnessed in actuators for satellites and spacecraft, enabling automatic deployment of structures or adjusting shapes based on temperature changes.

Couplings and seals: Ni-Ti alloys are used in mechanical couplings and sealing components that need to perform in high-stress environments while retaining shape and performance over long periods.

Automotive Industry:

Nickel-titanium alloys are used in automotive applications, particularly for high-performance components. Some applications include:

Shock absorbers: The superelasticity of Ni-Ti alloys allows for the creation of shock absorbers and suspension components that adapt to stress and return to their original shape after deformation.