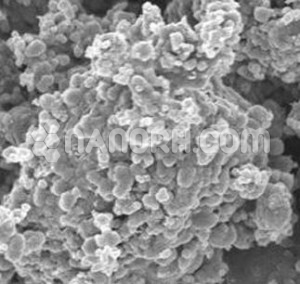

Silicon Carbide MicroPowder, SiC, (99+%, APS 40um(can be customized))

High-grade refractory material; Special use material for polishing abrasive; Ceramic bearings; Ceramic engine parts; Grinding wheels; Textile ceramics; High-frequency ceramics; Hard disc and a support for multichip modules; High-temperature and high-power semiconductors; High-temperature ceramic bearings; High-temperature fluid transport parts………..

| Silicon Carbide Micro Powder | |

| Product No | NRE-11218 |

| CAS No. | 409-21-2 |

| Formula | SiC |

| Molecular Weight | 40.09g/mol |

| APS | <40um(can be customized) |

| Purity | 99+% |

| Density | 3.16g/cm3 |

| Color | Gray |

| Melting Point | 2830°C |

| Boiling Point | NA |

Silicon Carbide micropowder

Silicon Carbide MicroPowder (SiC) is a compound of silicon and carbon. It occurs in nature as the extremely rare mineral moissanite. Due to its exceptional properties, it has found a wide range of applications in various fields. Silicon carbide powder, in particular, is utilized in numerous industrial and commercial applications, owing to its unique combination of properties. Some of the key applications of silicon carbide powder are as follows:

Abrasives: Silicon carbide powder is widely used as an abrasive due to its exceptional hardness. It is employed in the production of grinding wheels, sandpaper, and other abrasives, particularly for machining hard materials and grinding non-ferrous metals.

Refractories and Ceramics: Silicon carbide powder is used in the production of refractory materials and ceramics due to its high melting point, excellent thermal conductivity, and resistance to thermal shock. It finds applications in the production of kiln furniture, crucibles, and other high-temperature components.

Electronics and Semiconductors: Silicon carbide has superior properties that make it suitable for use in electronic components, such as high-temperature and high-power semiconductors. It is used in the production of LEDs, diodes, and other electronic devices.

Automotive and Aerospace Industries: Silicon carbide powder is employed in the production of high-performance ceramic parts for automotive and aerospace applications. It is used in manufacturing components such as brake discs, clutches, and bulletproof vests due to its exceptional hardness and lightweight properties.

Chemical Industry: Silicon carbide powder is used in various chemical processes as a catalyst support due to its high surface area and thermal stability. It finds applications in the production of chemicals, petrochemicals, and other industrial processes.

Metallurgy: Silicon carbide powder is utilized in the production of metal matrix composites, which are used in various industries for their superior mechanical and thermal properties. It is used in the production of lightweight, high-strength materials for aerospace and automotive applications.

Power Electronics: Silicon carbide powder is increasingly being used in the production of power electronics devices, such as power semiconductors, due to its ability to operate at high temperatures and voltages. It enables the development of more efficient and compact power electronic systems.

Coatings: Silicon carbide powder is used in the production of protective and wear-resistant coatings for various industrial applications. These coatings provide surfaces with improved hardness, wear resistance, and chemical inertness.

Energy Generation: Silicon carbide powder is used in the production of components for energy generation systems, such as solar inverters and wind turbine components, due to its high thermal conductivity and temperature resistance.