Silicon Graphene Carbon Nanotubes / CNTs Doped with 30wt% Si and 30wt% Graphene Nanopowder

Effectively improve the electrical conductivity and mechanical properties; Effectively enhance tensile strength, hardness and elastic modulus characteristics.

| Silicon Graphene Carbon Nanotubes | |

| Product No | NRE-39028 |

| CAS No. | NA |

| Purity | > 97% |

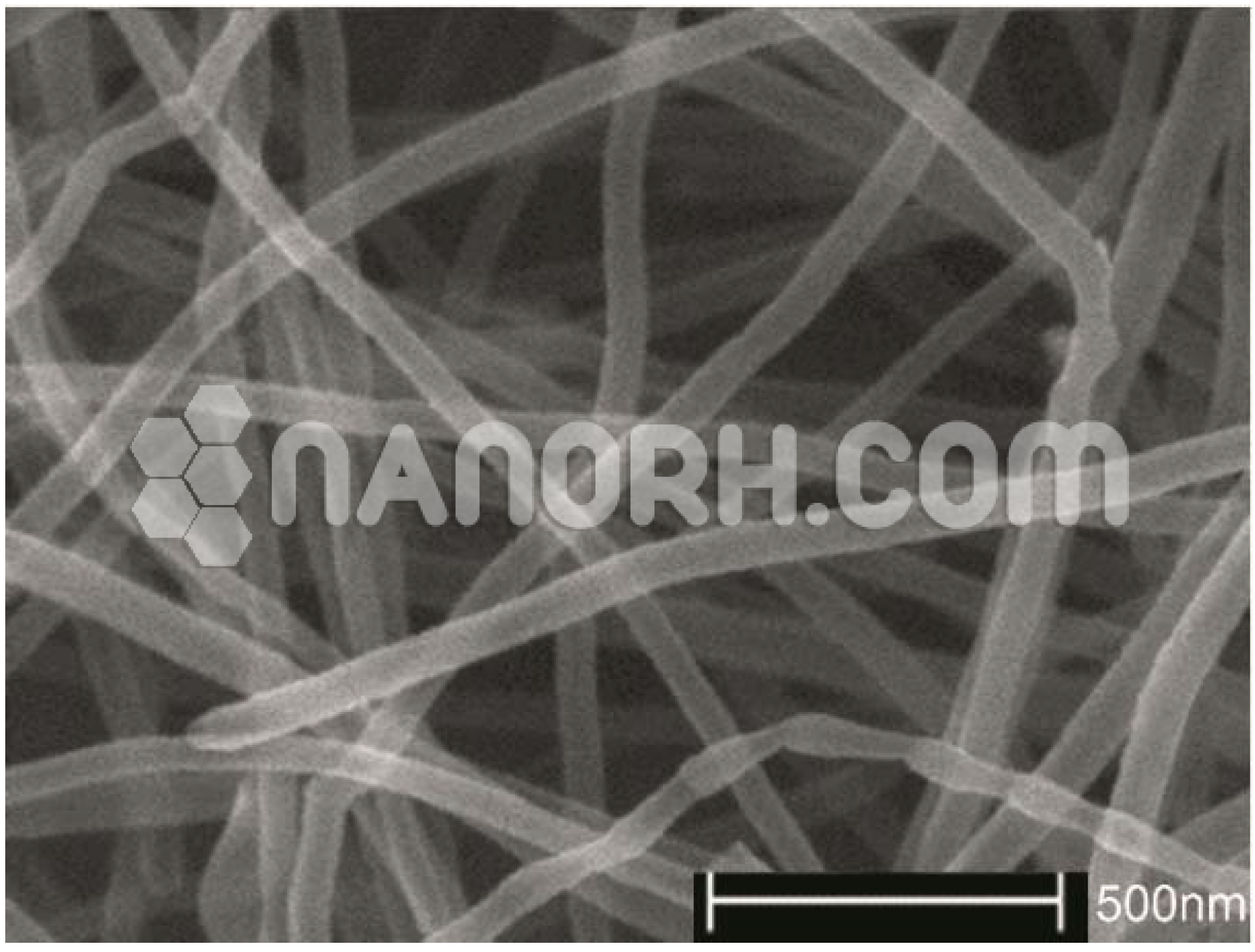

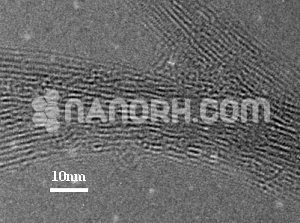

| Average Diameter | >55 nm |

| Average Length | 10-30 um (TEM) |

| Special Surface Area(SSA) | > 60 m2/g (BET) |

| Tap Density | 0.12 g/cm3 |

| True Density | 2.1 g/cm3 |

| Electric Conductivity | >100 s/cm |

Silicon Graphene Carbon Nanotubes

Introduction

Silicon Graphene Carbon Nanotubes combine three distinct but highly complementary nanomaterials: silicon, graphene, and carbon nanotubes (CNTs). Each of these components offers unique properties that, when integrated together, enhance the performance of the resulting material in a variety of applications.

Applications

Energy Storage Systems

Lithium-Ion Batteries (LIBs): Si-G-CNTs are highly effective in lithium-ion batteries. Silicon anodes offer a much higher theoretical capacity than conventional graphite anodes (approximately 10 times greater), but they suffer from significant volume expansion during charge and discharge cycles, leading to mechanical stress and poor cycle life. By integrating graphene and carbon nanotubes, these problems can be mitigated:

Graphene enhances electrical conductivity, facilitating faster charge/discharge rates.

Carbon nanotubes provide excellent mechanical reinforcement, reducing the stress caused by volume expansion and improving cycle stability.

Together, they create a structurally stable and highly conductive anode material that improves the capacity, cycling stability, and charge/discharge rates of lithium-ion batteries, making them suitable for electric vehicles (EVs), portable electronics, and grid storage.

Sodium-Ion Batteries (SIBs): Si-G-CNTs are also promising for sodium-ion batteries, an alternative to lithium-ion batteries. While sodium is more abundant and less expensive than lithium, it tends to have a larger ionic radius, which makes it more difficult to use with conventional anode materials.

cycling stability

high surface area and conductivity of graphene, along with the mechanical stability provided by CNTs, help create supercapacitors with higher energy density and faster charge/discharge rates. These supercapacitors can be used in applications requiring high power density and rapid energy release, such as electric vehicles, renewable energy systems, and consumer electronics.

Electronics and Optoelectronics

Flexible and Wearable Electronics: The combination of silicon, graphene, and CNTs allows for the creation of flexible and wearable electronics. Silicon provides semiconductor functionality, while graphene and CNTs offer flexibility, electrical conductivity, and mechanical strength. This hybrid material can be used in wearable sensors, smart clothing, and flexible displays, where both performance and mechanical flexibility are essential.

High-Performance Transistors and Sensors: Si-G-CNTs are promising materials for transistors and sensors in nanoelectronics. Silicon is already widely used in traditional semiconductor devices, while graphene and CNTs enhance charge transport, thermal conductivity, and mechanical strength. These hybrid materials could lead to the development of high-performance, low-power electronic devices, high-frequency transistors, and nano-scale sensors.

Transparent Conductive Films: Graphene and CNTs are well-known for their use in transparent conductive films for applications like touchscreens, solar cells, and LED displays. When combined with silicon, this hybrid material can offer enhanced conductivity and mechanical stability, making it suitable for large-area applications in transparent electronics.