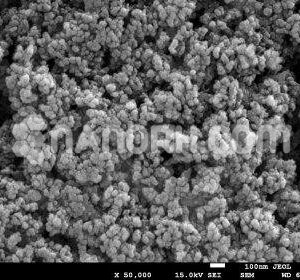

Stainless Steel Powder

Features: Stainless steel powder metallurgy is one of the main raw material for powder metallurgy, injection molding, 3D printing, diamond tools, carbide, thermal spraying materials and other products industries.

| Stainless Steel Powder | |

| Product No | NRE-9040 |

| CAS No. | 65997-19-5 |

| Yield Strength | 170 MPa |

| Tensile Strength | 485 MPa |

| APS | <40 um (can be customized) |

| Purity | 99.9% |

| Color | Gray black |

| Density | 7.7-8.0 g/cm³ |

| Melting Point | 1400-1535°C |

| Boiling Point | NA |

Stainless Steel Powder

In metallurgy, stainless steel, also known as stainless steel or stainless steel (stainless steel), is a steel alloy with a minimum of 10.5% by mass.

Stainless steels are known for their corrosion resistance, which increases with increasing chromium content. Molybdenum additions increase corrosion resistance in acid reduction and pitting attack in chloride solutions. Therefore, there are numerous grades of stainless steel with different contents of chromium and molybdenum to adapt to the environment that the alloy must withstand. The resistance of stainless steel to corrosion and stains, low maintenance, and familiar brightness make it an ideal material for many applications where both steel resistance and corrosion resistance are required.

Stainless steels are rolled into sheets, plates, bars, wires, and tubes for use in kitchen utensils, cutlery, surgical instruments, large household appliances; building material in large buildings, such as the Chrysler building; industrial equipment (for example, in paper mills, chemical plants, water treatment); and storage tanks and cisterns for chemicals and foodstuffs (eg tankers for chemicals and tanks). The corrosion resistance of stainless steel, the ease with which it can be cleaned and steam sterilized and the need for other surface coatings have also influenced its use in commercial kitchens and food processing plants.