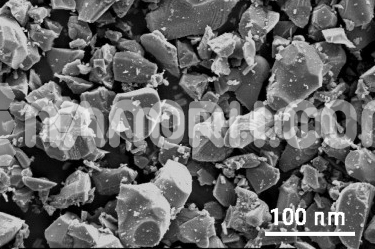

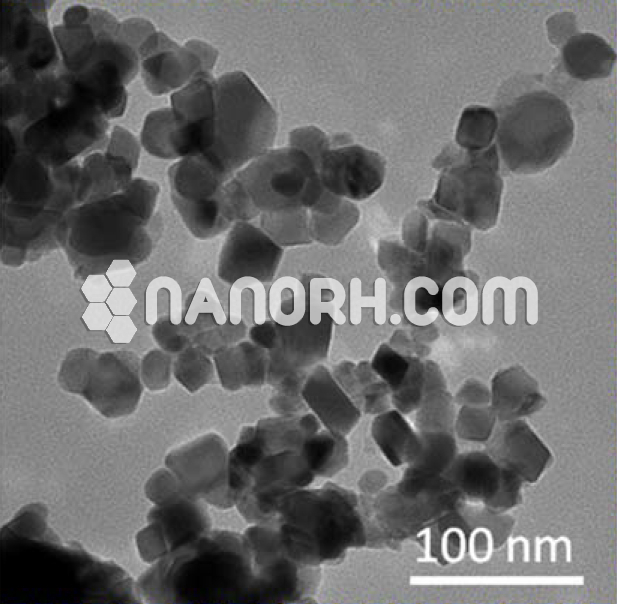

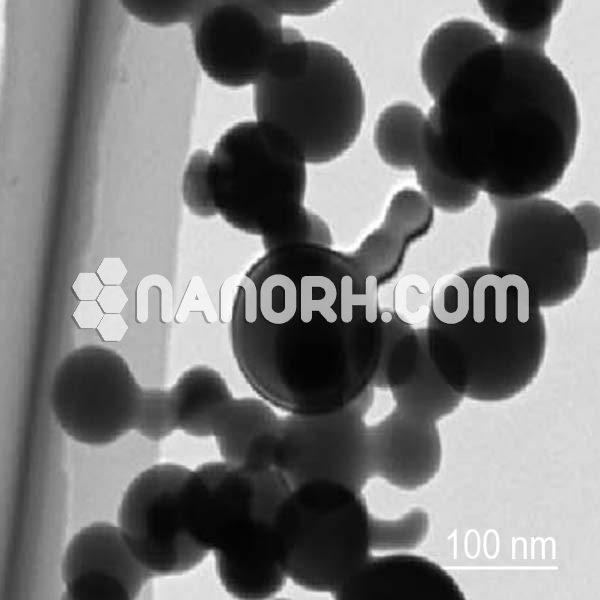

Titanium Carbide Nanoparticles / TiC NanoPowder (TiC, High Purity 99.9%, 100nm, cubic)

Titanium Carbide Nanoparticles / TiC NanoPowder -The product possesses high purity, narrow range particle size distribution. Also, the product has a good conductivity and chemical inert ability to steel and iron. ..

| Titanium Carbide Nanoparticles | |

| Product No | NRE-5233 |

| CAS No. | 12070-08-5 |

| Formula | TiC |

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Black |

| Molecular Weight | 59.89 g/mol |

| Density | 4.93 /cm3 |

| Melting Point | 3160 °C |

| Boiling Point | 4,820 °C |

Titanium Carbide Nanoparticles / TiC NanoPowder General Features:

1. The product possesses high purity, narrow range particle size distribution. Also, the product has a good conductivity and chemical inert ability to steel and iron.

2. The product’s melting point is about 3200 °C. It is an essential component of cemented carbide with high hardness, corrosion resistance, thermal stability, etc. Also, it is often used in the manufacture of wear-resistant materials, cutting tools, mold, metal melting crucible and many another field prospect.

Applications:

1) TiC is used in manufacturing wear-resistant materials, cutting tools etc. TiC coating can improve the alloy, abrasive steel bearings, nozzles, cutting tools wear resistance; 2) Titanium carbide ceramic is a good optical material; 3) plastic enhanced conductive material nucleating agents……

General Features:

1. The product possesses high purity, narrow range particle size distribution. Also, the product has a good conductivity and chemical inert ability to steel and iron.

2. The product’s melting point is about 3200 °C. It is an essential component of cemented carbide with high hardness, corrosion resistance, thermal stability, etc. Also, it is often used in the manufacture of wear-resistant materials, cutting tools, mold, metal melting crucible, and many other field prospects.