| Tungsten Boride Sputtering Targets | |

| Product No | NRE-43589 |

| CAS No. | 12007-09-9 |

| Formula | WB |

| Molecular Weight | 194.65 |

| Purity | >99.9% |

| Density | 15.3 g/cm3 |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Tungsten Boride Sputtering Targets

Introduction:

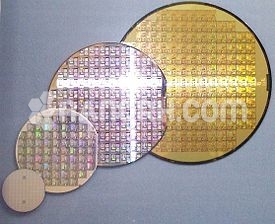

Tungsten boride sputtering targets is a compound known for its exceptional hardness, thermal stability, and wear resistance. These properties make tungsten boride a valuable material in various industrial applications, especially in hard coatings and cutting tools. Sputtering targets made from tungsten boride are used in physical vapor deposition (PVD) processes to create high-performance thin films with specific mechanical and thermal characteristics.

Applications:

Cutting Tools: Tungsten boride coatings enhance the durability and wear resistance of cutting tools, making them suitable for machining hard materials.

Wear-Resistant Coatings: WB is used to produce wear-resistant coatings on various components, including pumps, valves, and mechanical parts, improving their lifespan and performance.

High-Temperature Applications: The thermal stability of tungsten boride allows it to be used in high-temperature environments, such as in aerospace and automotive components.

Electrical Contacts: Tungsten boride can serve as a conductive layer in electrical contacts, benefiting applications where good conductivity and wear resistance are essential.

Surface Hardening: Coatings made from tungsten boride can improve surface hardness and resistance to abrasion, making them suitable for protective applications in various industries.

Advantages

High Hardness: Tungsten boride exhibits superior hardness, making it ideal for applications requiring wear resistance.

Thermal Stability: The compound maintains its properties under high-temperature conditions, ensuring reliability in demanding environments.

Controlled Composition: The sputtering process allows for precise control over the composition and thickness of the deposited films, tailored to specific applications.