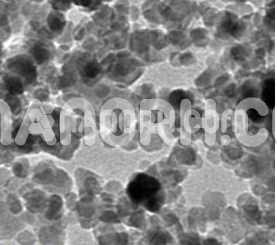

Tungsten Carbide Nanoparticles / Nanopowder (WC, High purity, 99.95%, 30-100 nm)

Tungsten Carbide Nanoparticles

| Tungsten Carbide Nanoparticles | |

| Product No | NRE-5248 |

| CAS No. | 12070-12-1 |

| Formula | WC |

| APS | <100nm (Can be Customized) |

| Purity | 99.95% |

| Color | Grey-Black |

| Molecular Weight | 195.85g/mol |

| Density | 15.6g/cm3 |

| Melting Point | 2785-2830°C |

| Boiling Point | 6000°C |

Tungsten carbide Nanoparticles (WC) Physical and Chemical Properties:

Tungsten carbide nanoparticles (WC nanoparticles) have gained significant attention due to their exceptional properties, such as high hardness, wear resistance, and mechanical strength. These properties, when combined with the high surface area and reactivity of the nanoparticles, make them ideal for a wide range of applications across various industries. Below are some key areas where tungsten carbide nanoparticles are applied:

Cutting Tools and Wear-Resistant Components

Tungsten carbide nanoparticles are widely used in the production of cutting tools and wear-resistant components due to their hardness and durability. The fine particle size of the nanoparticles enhances the cutting edge and reduces wear during high-speed machining and metalworking.

Drill Bits and Milling Tools: WC nanoparticles improve the performance of drilling and milling tools, extending tool life and increasing cutting efficiency.

Saws and Abrasive Tools: These nanoparticles are incorporated into saw blades, grinding wheels, and abrasive tools for superior wear resistance and cutting ability.

Wear-Resistant Coatings

Tungsten carbide nanoparticles are often used to produce wear-resistant coatings on machinery parts, tools, and equipment that undergo frictional wear, abrasion, or corrosion. These coatings significantly extend the service life of the components and maintain their performance in harsh conditions.

Industrial Coatings: WC nanoparticles are used to coat critical parts in industries like mining, construction, and oil extraction, offering superior protection against abrasion and wear.

Coatings for Pumps and Valves: The nanoparticles are used in coatings for pumps, valves, and seals to ensure durability under abrasive conditions.

Lubricants and Friction Reduction

WC nanoparticles can be added to lubricants to reduce friction between moving parts in mechanical systems. They act as solid lubricants, creating a thin lubricating layer that helps reduce wear, increase efficiency, and improve the lifespan of components.

High-Performance Lubricants: WC nanoparticles are used in engine oils, industrial lubricants, and hydraulic fluids to improve friction reduction and wear resistance in machinery and vehicles.

Bearings and Gearboxes: Incorporating WC nanoparticles in lubricants helps reduce friction in bearings, gears, and other moving components, enhancing the performance and lifespan of equipment.