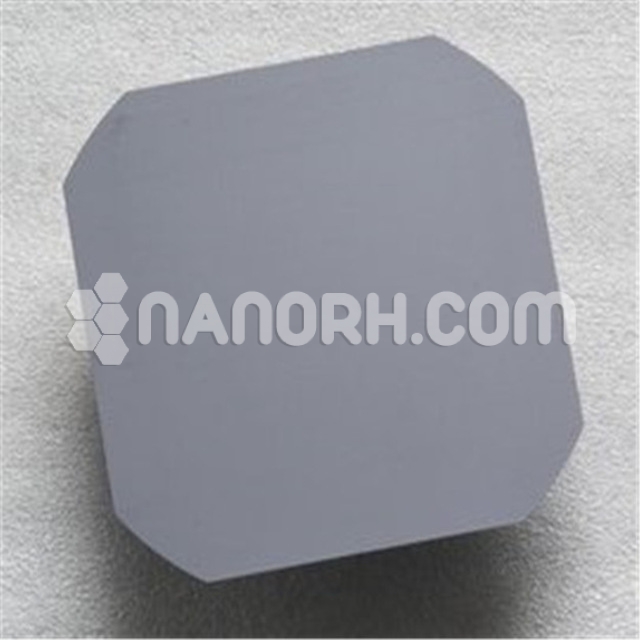

| Carbon Sputtering Target | |

| Product No | NRE-43024 |

| CAS No. | 7440-44-0 |

| Formula | C |

| Molecular Weight | 12.01 g/mol |

| Purity | >99.99% |

| Density | 1.8 – 2.1 g/cm³ |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Electronegativity | NA |

Carbon Sputtering Target

Carbon sputtering targets are used in a variety of applications beyond the ones previously mentioned. Here’s a look at some additional or more specific applications where carbon sputtering targets can be valuable.

Graphene and Carbon Nanotubes:

Advanced Materials: Carbon sputtering targets can be used to deposit thin films of graphene or carbon nanotubes. These materials are renowned for their exceptional electrical, thermal, and mechanical properties, making them useful in high-performance electronics, nanotechnology, and advanced materials research.

Hard Coatings:

Tool Coatings: Sputtered carbon coatings, particularly DLC, are applied to cutting tools, molds, and dies to improve hardness and reduce friction. This extends the lifespan of tools and enhances their performance in machining and manufacturing processes.

Optical and Spectroscopic Applications:

Reflective Coatings: Carbon films can be used as reflective coatings in optical systems, including mirrors and beam splitters, due to their ability to reflect a wide range of wavelengths.

Spectroscopic Filters: Carbon-based films can be employed as spectroscopic filters or in wavelength-selective coatings, enhancing the performance of optical spectroscopy instruments.

Surface Modification:

Functionalized Surfaces: Carbon sputtering targets can be used to deposit thin layers that modify the surface properties of materials. This can be applied to improve surface wettability, adhesion, or to create specific surface chemistry for applications in sensors or biomedical devices.

Gas Barrier Films:

Protective Layers: Carbon films, especially when sputtered to create thin, dense layers, can act as gas barriers. These are used in packaging applications to protect sensitive products from moisture and oxygen, extending their shelf life.

Electromagnetic Shielding:

Shielding Layers: Carbon films can provide electromagnetic shielding in various electronic and communication devices. The conductive properties of carbon materials help to block unwanted electromagnetic interference (EMI).

Thermal Management:

Heat Spreading: Carbon-based materials are sometimes used in thermal management applications to improve heat dissipation. Thin carbon films can spread heat effectively in electronic components and other devices requiring efficient thermal management.

Photoresists and Etch Masks:

Microfabrication: In semiconductor manufacturing and microfabrication, carbon films can be used as photoresists or etch masks. They help define patterns on substrates during the fabrication of microelectronic components.

Biomedical Implants:

Surface Coatings: Carbon coatings, including DLC, are used on biomedical implants such as artificial joints or dental implants. These coatings enhance biocompatibility, reduce friction, and improve the wear resistance of the implants.