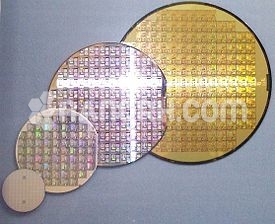

| Cerium Boride Sputtering Targets | |

| Product No | NRE-43356 |

| CAS No. | 12008-02-5 |

| Formula | CeB6 |

| Molecular Weight | 204.98 |

| Purity | >99.9% |

| Density | 4.80 g/cm3 |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Cerium Boride Sputtering Targets

Cerium boride (CeB₆) sputtering targets are used in various advanced applications due to their unique properties, including high hardness, high thermal stability, and electrical conductivity. Here’s an overview of some key product applications for cerium boride sputtering targets.

Hard Coatings:

Wear-Resistant Coatings: Cerium boride is used to create extremely hard and wear-resistant coatings. These coatings are applied to cutting tools, drilling bits, and other industrial components to extend their lifespan and improve performance by reducing friction and wear.

High-Temperature Applications:

Thermal Barrier Coatings: The high thermal stability of cerium boride makes it suitable for use in thermal barrier coatings. These coatings can withstand extreme temperatures, making them ideal for applications in aerospace and high-temperature industrial processes.

Electrical Contacts and Conductors:

Conductive Films: Cerium boride can be used to deposit conductive films in electronic devices. Its electrical conductivity and stability make it useful for creating reliable electrical contacts and conductive layers in various electronic components.

Magnetic Materials:

Magnetic Coatings: Cerium boride’s properties can be utilized in magnetic materials for specialized applications. While not a magnetic material itself, cerium boride can be used in combination with other materials to create thin films with specific magnetic properties.

Catalysis:

Catalyst Supports: Cerium boride may be used as a support material for catalysts in various chemical reactions. Its stability at high temperatures and unique chemical properties can enhance the performance of catalytic processes.

Optical Coatings:

Protective Layers: Cerium boride thin films can be used in optical coatings to provide durable and protective layers. These coatings can improve the performance and longevity of optical components by enhancing their resistance to abrasion and environmental damage.

Refractory Materials:

High-Temperature Environments: Due to its high melting point and thermal stability, cerium boride can be used in refractory materials that need to withstand extreme conditions, such as in high-temperature furnaces or reactors.

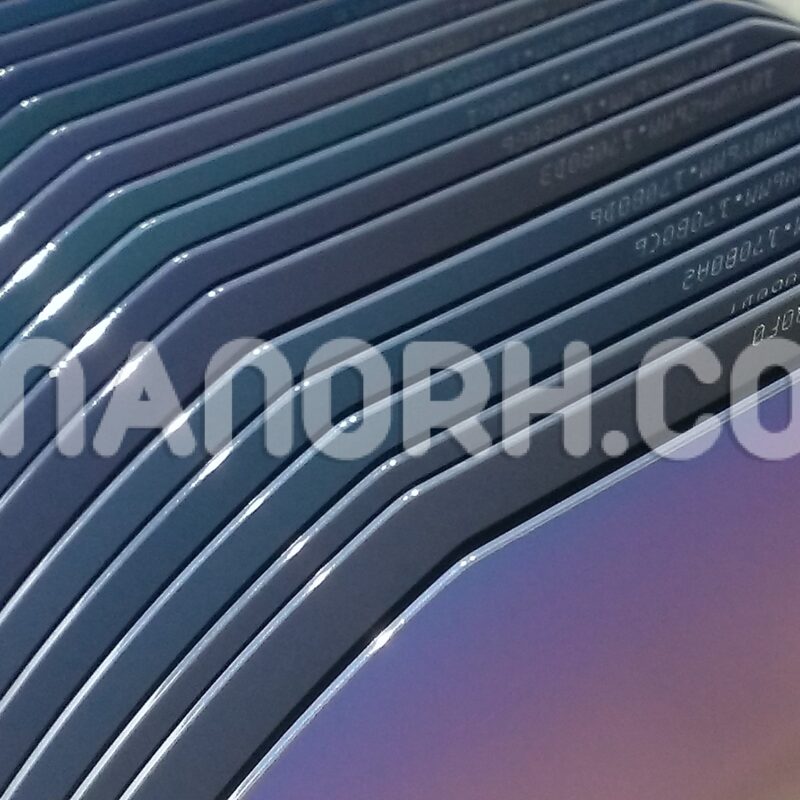

Microelectronics:

Thin-Film Deposition: Cerium boride is used in the deposition of thin films for microelectronics applications. Its properties can contribute to the performance and reliability of semiconductor devices and other microelectronic components.