| Chromium Nickel Alloy Sputtering Targets | |

| Product No | NRE-43369 |

| CAS No. | NA |

| Formula | Cr-Ni |

| Molecular Weight | NA |

| Purity | >99.9% |

| Density | NA |

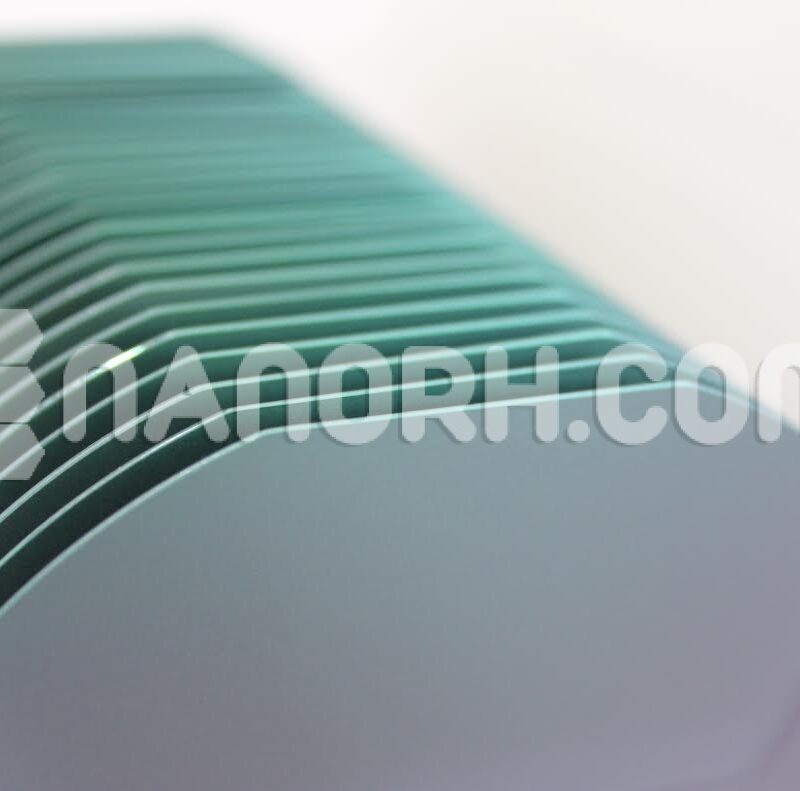

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Chromium Nickel Alloy Sputtering Targets

Chromium-nickel alloy sputtering targets are used in a variety of advanced coating applications due to their unique properties. Here are some key applications.

Hard Coatings: These targets are used to deposit hard, wear-resistant coatings on tools and components, improving their durability and performance. The alloy’s properties contribute to coatings with high hardness and resistance to abrasion.

Corrosion-Resistant Coatings: Chromium and nickel both provide excellent corrosion resistance, so coatings made from this alloy are used in environments where components are exposed to harsh chemicals or moisture.

Decorative Coatings: The alloy can be used to produce aesthetically pleasing and durable decorative finishes on products such as jewelry, automotive parts, and electronics.

Magnetic Materials: In some applications, these targets are used to deposit magnetic thin films for use in magnetic storage media and other electronic devices.

Electrical Contacts: The alloy’s properties make it suitable for depositing coatings on electrical contacts and connectors, where it can help reduce electrical resistance and enhance reliability.

Optical Coatings: Chromium-nickel alloy coatings can also be used in optical coatings where specific optical properties, such as reflectivity or anti-reflectivity, are required.

These applications leverage the alloy’s combination of hardness, corrosion resistance, and versatility, making it a valuable material in various industrial processes.