| Fe Spherical Powder | |

| Product No | NRE-8026 |

| CAS No. | 7439-89-6 |

| Formula | Fe |

| Molecular Weight | 55.85 g/mol |

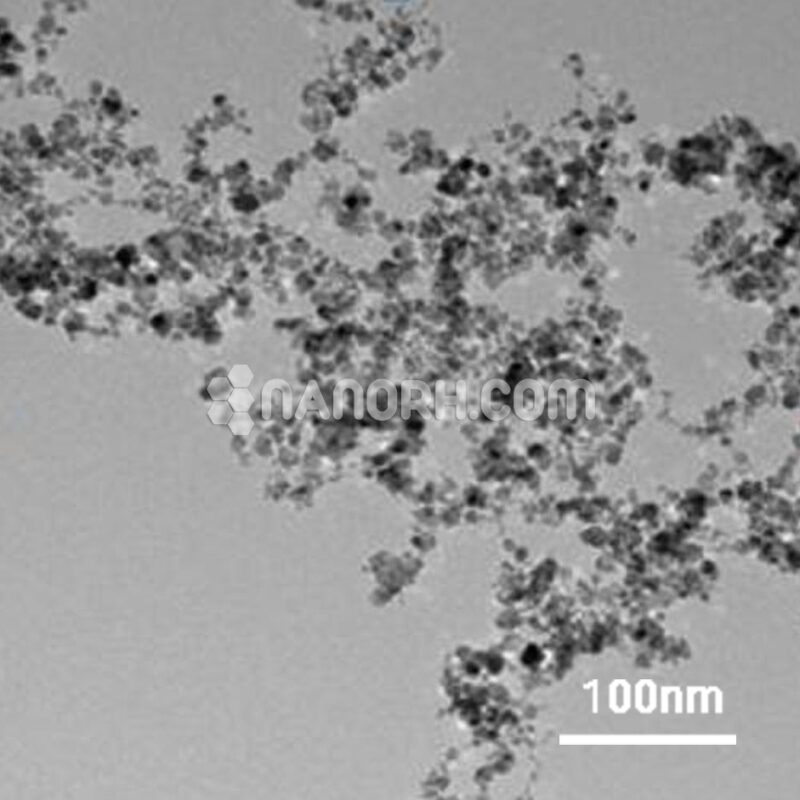

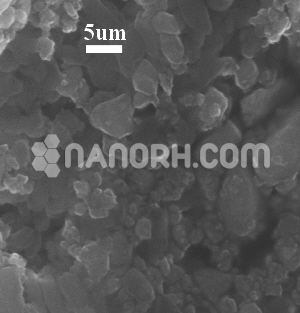

| APS | 3um (can be customized) |

| Purity | 99.9% |

| Color | Dark Grey |

| Density | 7.86 g/cm3 |

| Melting Point | 1538 °C |

| Boiling Point | 2862 °C |

Fe Spherical Powder (Fe, Spherical, average particle size, 3um, 99.9%)

Iron spherical powder, also known as iron microspheres or iron micro-powder, has several applications across various industries due to its unique properties. These tiny iron particles are typically spherical in shape and can range in size from nanometers to micrometers. Some of the common applications of iron spherical powder include:

Additive Manufacturing (3D Printing):

Iron spherical powder can be used as a feedstock material in metal additive manufacturing processes like selective laser melting (SLM) and electron beam melting (EBM). It allows for the creation of complex, high-strength metal parts with precise geometries.

Magnetic Materials:

Iron microspheres are often used in the production of magnetic materials, including magnetic inks, magnetic fluids, and magnetic composites. These materials find applications in data storage, sensors, and magnetic resonance imaging (MRI) contrast agents.

Catalysis:

Iron nanoparticles can act as efficient catalysts in various chemical reactions. Their high surface area and reactivity make them valuable in catalytic processes for hydrogenation, dehydrogenation, and other chemical transformations.

Biomedical Applications:

Iron spherical powder can be used in the development of contrast agents for magnetic resonance imaging (MRI). Superparamagnetic iron oxide nanoparticles, which exhibit enhanced magnetic properties at the nanoscale, are used to improve the imaging contrast in MRI scans.

Environmental Remediation:

Iron nanoparticles are employed in environmental applications, such as the remediation of contaminated groundwater and soil. They can help in the degradation of organic pollutants and the reduction of heavy metal ions.

Energy Storage:

Iron microspheres can be used as anode materials in rechargeable lithium-ion batteries and other energy storage systems. They offer high capacity and good cycling stability.

Metallurgy and Powder Metallurgy:

In the field of metallurgy and powder metallurgy, iron spherical powder can be used as a raw material for producing sintered parts, high-density components, and alloy powders.

Electronics and Electromagnetic Shielding:

Iron micro-powder is used in the manufacturing of electromagnetic interference (EMI) shielding materials and conductive inks for printed electronics. Its electrical conductivity and magnetic properties make it suitable for these applications.

Coatings and Paints:

Iron microspheres can be incorporated into coatings and paints to provide corrosion resistance, thermal insulation, and heat-reflective properties.

Aerospace and Automotive:

Iron micro-powder can be utilized in the aerospace and automotive industries for lightweight structural components, fuel cells, and other high-performance applications.

Filtration and Water Treatment:

Iron nanoparticles can be used in water filtration systems for the removal of contaminants, such as arsenic and heavy metals.