| Kaolin Nanoclay | |

| Product No | NRE-6016 |

| CAS No. | 1332-58-7 |

| Formula | Al2Si2O5(OH)4 |

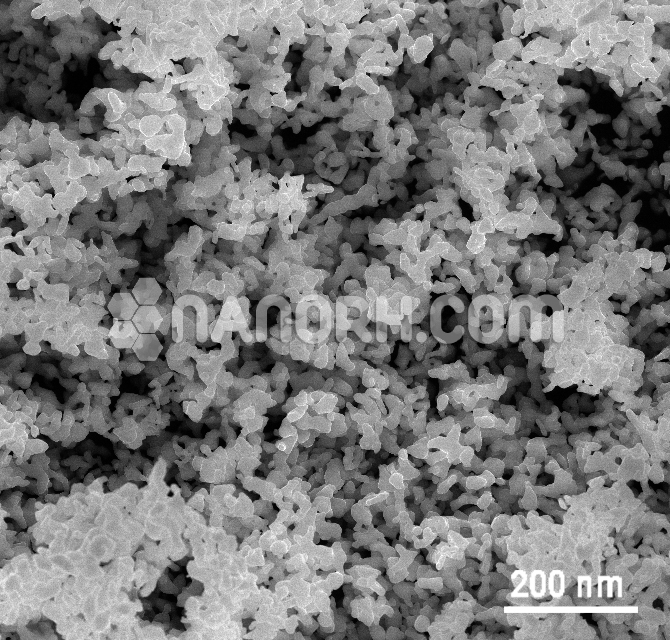

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | White |

| Molecular Weight | 258.2 g/mol |

| Density | 2.65 g/cm3 |

| Melting Point | 740-1785°C |

| Boiling Point | NA |

Kaolin Nanoclay

Use of Kaolin Nanoclay as in controlled release technology for a range of active agents. This mineral is extensively used in industry for ceramics, cements and fertilisers. Besides these it has enormous potential applications because of their peculiar tubularly shaped particles normally found in this mineral. Nanoclay has also been used as a petroleum cracking catalyst in the past.

Nanoclay used for active release of corrosion inhibitors. In this approach corrosion coatings composed of hybrid sol-gel films were doped within Nanoclay so they were able to release entrapped corrosion inhibitors in a controllable way. A silica-zirconia-based hybrid film can be used as an anticorrosion coating deposited on aluminium alloy. Kaolin Nanoclay with inner voids loaded by corrosion inhibitors (2- mercaptobenzothiazole) and outer surfaces covered layer-by-layer with polyelectrolyte multilayers were introduced into the hybrid films.

Kaolin Nanoclay (HNTs) used with linear low density polyethylene (LLDPE) to prepare composites with enhance mechanical and prominant flame retardant properties. Poly Ethylene graft was used as interfacial modifier in the LLDPE/HNTs composites. HNTs have proved to be a promising reinforcing and flame retardant nano-filler for LLDPE. This mechanical properties, flame retardancy, as well as thermal stability of the composites can be further enhanced by the addition of the graft copolymer.