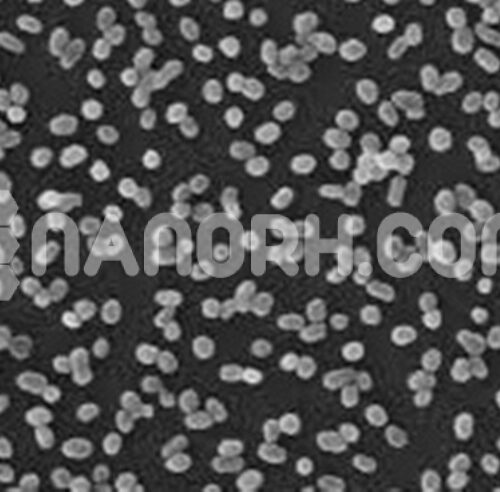

Molybdenum Disilicide Powder / MoSi2 Powder (MoSi2, 1-3um, 99.9%, Alpha)

Molybdenum Disilicide Powder

| Molybdenum Disilicide Powder | |

| Product No | NRE-11183 |

| CAS No. | 12136-78-6 |

| Formula | MoSi2 |

| Molecular Weight | 152.11 g/mol |

| APS | 1-3um(can be customized) |

| Purity | 99.9% |

| Density | 6.3g/cm3 |

| Color | Gray |

| Melting Point | 2,030 °C |

| Boiling Point | NA |

Molybdenum Disilicide Powder

Molybdenum disilicide (MoSi2) is a refractory ceramic material with a high melting point and excellent oxidation resistance at high temperatures. It has various applications owing to its unique properties. One of the common forms in which it is used is as a powder. Here are some of the applications of molybdenum disilicide powder:

Heating Elements: One of the primary applications of molybdenum disilicide powder is in the production of heating elements. These heating elements are used in high-temperature furnaces, especially those that require operation at temperatures above 1000°C. The exceptional oxidation resistance of molybdenum disilicide makes it an ideal material for this purpose.

Ceramics and Glass Production: MoSi2 powder is also used in the production of ceramics and glass, particularly in the sintering process. Its high-temperature resistance and thermal stability make it a valuable component in the manufacturing of these materials.

Semiconductor Industry: In the semiconductor industry, molybdenum disilicide powder finds application in various processes, such as the production of diffusion barriers, thin films, and other electronic components. Its excellent electrical conductivity and thermal stability make it suitable for these applications.

Coatings and Surface Treatment: MoSi2 powder is used for coating and surface treatment purposes due to its high-temperature stability and resistance to oxidation. It can be applied to improve the properties of materials, such as enhancing their resistance to wear, corrosion, and high-temperature degradation.

Additive Manufacturing: With the rise of additive manufacturing technologies, molybdenum disilicide powder has found applications in the 3D printing of high-temperature components and parts. Its unique properties make it a suitable material for producing complex shapes that require high-temperature stability and resistance.

Ceramic Composites: MoSi2 powder is also used in the production of ceramic composites, which are materials with enhanced mechanical and thermal properties. These composites find applications in various industries, including aerospace, automotive, and energy, where high-temperature performance is critical.

Refractory Materials: Molybdenum disilicide powder is used as an additive in the production of refractory materials that are used in high-temperature applications, such as in the manufacturing of crucibles, furnace linings, and other components that require resistance to extreme temperatures and harsh environments.