| Stainless Steel 316L Spherical Powder | |

| Product No | NRE-9050 |

| CAS | 65997-19-5 |

| Purity | 99.9% |

| Formula | NA |

| APS | <40um (can be customized) |

| Color | Gray |

| Molecular Weight | NA |

| Density | 7.9 g/cm³ |

| Melting Point | 1375 – 1400°C |

| Boiling Point | NA |

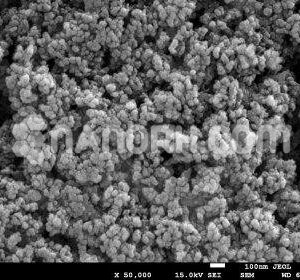

Stainless Steel 316L Spherical Powder

Applications

Additive Manufacturing (3D Printing)

Metal 3D Printing (SLM, DMLS): Stainless Steel 316L spherical powder is widely used in Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). These techniques use high-powered lasers to melt and fuse the powder layer by layer to create complex and custom parts. The spherical shape of the powder enables smooth powder flow during the printing process, ensuring a high-quality finish and strong part performance.

Aerospace and Aviation

Structural Components: The 316L spherical powder is frequently used in aerospace manufacturing to produce lightweight, high-strength components. Parts such as engine components, brackets, and fasteners benefit from the alloy’s resistance to heat and corrosion.

Fuel Systems: The alloy is used in parts that are exposed to aggressive environments such as fuel lines, fuel nozzles, and engine components that require both strength and resistance to high temperatures.

Medical Devices and Implants

Surgical Implants: 316L stainless steel’s excellent biocompatibility and corrosion resistance make it a preferred material for medical implants such as hip replacements, dental implants, and bone screws. The spherical powder is particularly useful for 3D printing customized implants with high precision.

Medical Instruments: The fine powder is also used in the production of surgical instruments, where high strength, resistance to corrosion, and precision are required.

Marine and Offshore Applications

Saltwater Environments: In marine applications, stainless steel 316L is highly valued for its ability to resist pitting and corrosion caused by saltwater. It is used to produce parts like seawater piping, heat exchangers, and other marine hardware where durability and corrosion resistance are crucial.

Offshore Equipment: Equipment exposed to the harsh conditions of offshore drilling, such as pumps and valves, also benefit from the material’s properties.