Zirconium Copper Aluminium Silver Alloy Sputtering Target (ZrCuAlAg, Purity: 99.99%)

Zirconium Copper Aluminium Silver Alloy Sputtering Target

| Zirconium Copper Aluminium Silver Alloy Sputtering Target | |

| Product No | NRE-43186 |

| CAS No. | NA |

| Formula | ZrCuAlAg |

| Molecular Weight | NA |

| Purity | >99.9% |

| Density | NA |

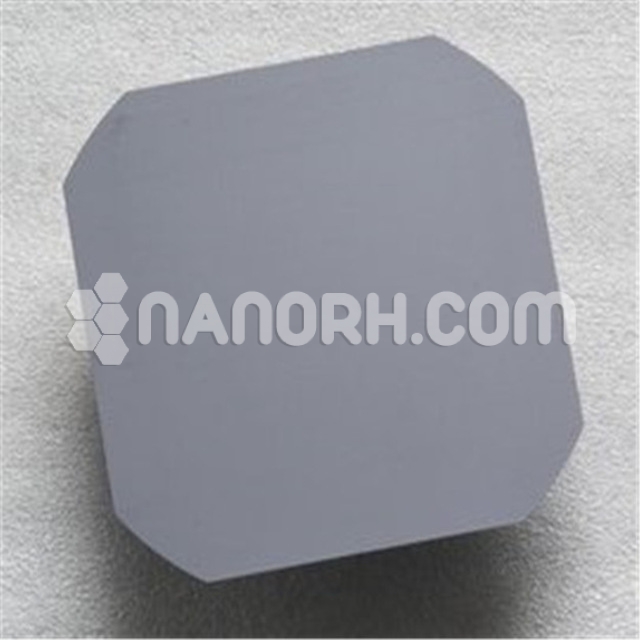

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

ZrCuAlAg Alloy Sputtering Target

The ZrCuAlAg Alloy Sputtering Target is used in various specialized applications due to its unique combination of properties. These properties, such as good thermal stability, electrical conductivity, and resistance to oxidation, make it suitable for thin-film deposition through sputtering. Here are the key applications:

Thin Film Deposition for Electronics:

ZrCuAlAg alloy targets are often used in the electronics industry for the deposition of thin films. These films are used in various electronic components such as capacitors, resistors, and semiconductors. The alloy provides excellent electrical and thermal conductivity, making it ideal for producing components that require stable performance in electronic devices.

Optical Coatings:

The alloy is also applied in the creation of optical coatings like mirrors, lenses, and protective coatings for optical devices. These coatings are durable, highly resistant to environmental degradation, and improve the performance of optical components.

Magnetic Materials:

ZrCuAlAg sputtering targets are used in magnetic thin films deposition, which are essential in data storage, magnetic sensors, and hard drives. The materials exhibit the necessary magnetic properties, which makes them ideal for use in magnetic recording media and other magnetic applications.

Hard Coatings for Wear Resistance:

The alloy is used for hard coatings that increase the wear resistance and durability of materials. These coatings are applied in industrial tools, machine components, and wear-resistant surfaces in harsh environments, improving the lifespan and performance of equipment.

Corrosion-Resistant Coatings:

Due to the high corrosion resistance of zirconium and copper, ZrCuAlAg sputtering targets are used to produce protective coatings for components exposed to harsh chemicals and extreme environments, such as in aerospace, marine, or chemical industries.

Biocompatible Coatings:

The alloy’s properties can also be beneficial for biomedical applications, such as coatings for medical implants and devices. The combination of elements in the alloy ensures good biocompatibility and resistance to corrosion in the human body.