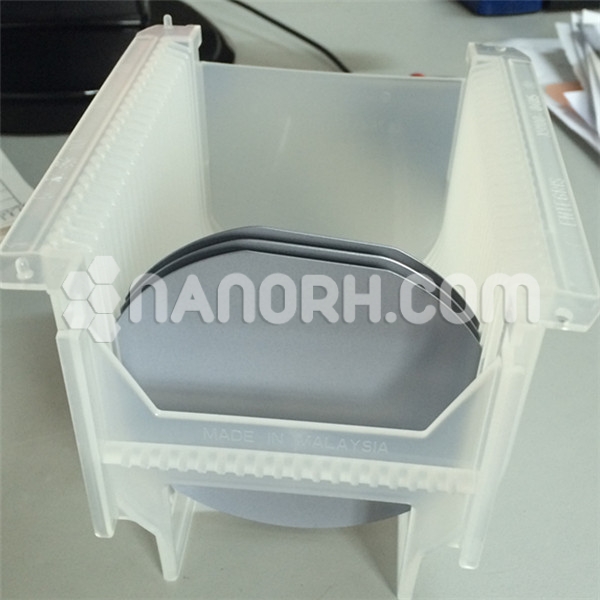

| ZIRCONIUM Crucibles | |

| Product No | NRE-47011 |

| CAS | 7440-67-7 |

| Purity | >99.9% |

| Capacity | 5ml |

| Apparent Porosity | NA |

| Cold Bending Strength | NA |

| Max Service Temperature | 2200 °C |

| Density | 6.5 g/cm³ |

| Melting Point | 1852 °C |

| Boiling Point | 4377 °C |

ZIRCONIUM Crucibles

Introduction:

ZIRCONIUM crucibles are specialized containers made from ZIRCONIUM, a metal known for its excellent corrosion resistance, high melting point (approximately 1,855°C or 3,371°F), and low thermal conductivity. These properties make ZIRCONIUM crucibles ideal for various high-temperature applications, particularly in environments where chemical reactivity and purity are critical. ZIRCONIUM ability to withstand aggressive chemicals without degrading further enhances its suitability for specialized industrial and laboratory processes.

Applications

Chemical Processing:

Handling Corrosive Materials: Used extensively in chemical reactions involving acids, alkalis, and other reactive substances. ZIRCONIUM corrosion resistance ensures that the crucible remains inert, preserving the integrity of the chemical process.

Metallurgical Processes:

Melting and Casting: Employed for melting high-temperature metals and alloys, where the purity of the molten material is crucial. ZIRCONIUM crucibles help prevent contamination from other materials.

Nuclear Applications:

Radioactive Material Handling: Utilized in the nuclear industry for containing radioactive materials. ZIRCONIUM low neutron absorption cross-section makes it valuable in applications involving nuclear fuel and reactor components.

High-Temperature Research:

Material Testing: Commonly used in laboratories for high-temperature experiments in materials science, where precise thermal control and material stability are essential.

Sintering:

Advanced Ceramics: Employed in the sintering of ceramics and other advanced materials, providing a stable environment for achieving optimal material properties.

Biomedical Applications:

Used in the production of ZIRCONIUM-based materials for implants and medical devices due to ZIRCONIUM’s biocompatibility and resistance to corrosion.

Glass and Ceramics Production:

Utilized in the manufacture of specialty glasses and ceramics, where maintaining high temperatures without contamination is critical.

Thin Film Deposition:

Applied in the semiconductor industry for processes that require high purity and stable thermal conditions.

Reviews

There are no reviews yet.